From appleinsider.com

The next edition of the Apple Watch Ultra will feature titanium mechanical parts where some have been produced by 3D printing to save time and cost, says analyst Ming-Chi Kuo.

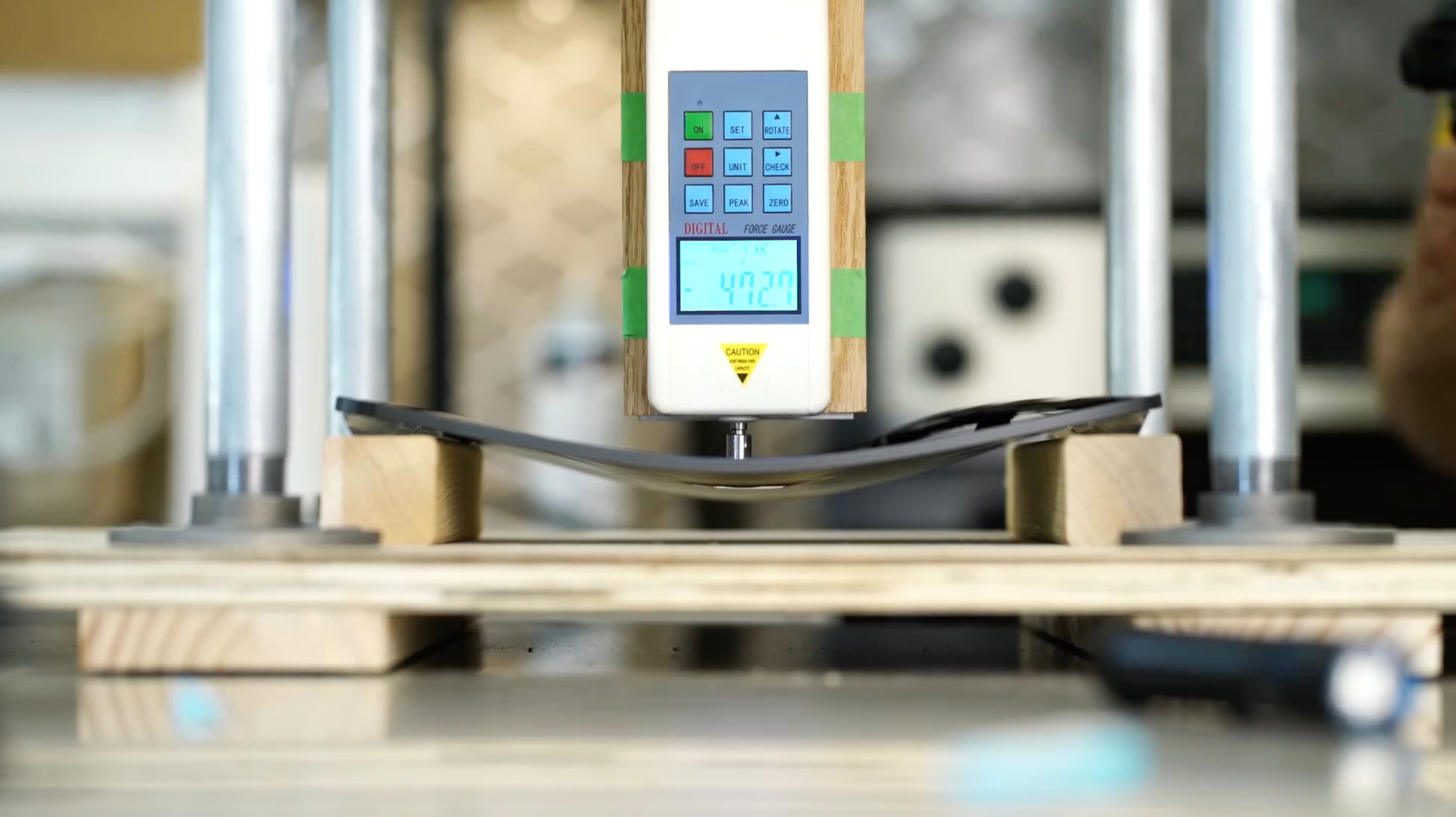

Apple is not likely to be turning to consumer 3D printers for the new Apple Watch Ultra, but reportedly it will be moving away from its regular CNC machining process, at least in part. Computerized Numerical Control (CNC) is the process of taking CAD designs and automatically manufacturing the parts by cutting at the material.

Analyst Ming-Chi Kuo says that Apple will continue to use CNC and that it will even be used to finish off elements of the 3D printed mechanical parts. But by moving to 3D printing, Kuo says that Apple can speed up the time taken for production — while simultaneously cutting down on costs.

2H23 New Apple Watch Ultra mechanical parts to adopt 3D printing technology; key suppliers including IPG Photonics, Farsoon and BLT / 2H23Apple Watch Ultra3DIPG Photonicshttps://t.co/PngNIIihC9

— (Ming-Chi Kuo) (@mingchikuo) July 14, 2023

In his full report, Kuo goes on to speculate that Apple will adopt 3D printing for other products. As well as the same savings in time and cost, he believes it will help improve on Apple’s ESG performance — the Environmental, Social and Governance metrics that concern a company’s sustainability.

A second generation of the Apple Watch Ultra is expected to be announced in the fall, possibly alongside the Apple Watch Series 9.

[ For more curated Apple news, check out the main news page here]

The post Apple will use 3D printing to make Apple Watch Ultra mechanical parts first appeared on appleinsider.com